Ever wondered how to make your printed project stand out from the competition and jump off the shelves to customers? Apart from an organization’s marketing efforts and selling points the best way to easily differentiate your printed products to get an edge over the competition is with embellishments. Embellishments are the individual decorative aspects of a larger printed piece that draw attention to certain areas of the print which are deemed important, or they can be used to create a more visually stunning printed piece. When implemented effectively by experienced craftsmen, embellishments can convince customers of the quality, care, dedication and attention to detail your organization provides its customers. Embellished pieces can also command a higher price point depending on the nature of the product, due to its luxurious look and feel.

There are various types of embellishments which can be employed in a number of diverse ways on your printed products. While some embellishments may be very obvious and jump off the print, others can remain more subtle and powerful. With nearly limitless possibilities and combinations of finishing techniques here are the major styles traditionally used:

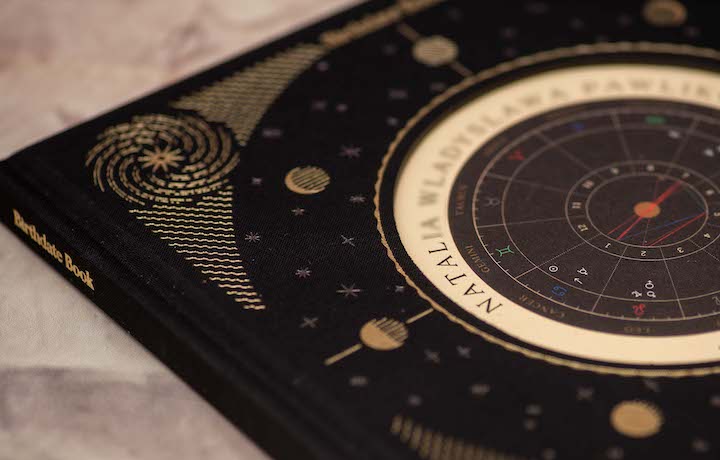

Foil Stamping:

Digital foil stamping consists of applying a hot stamping foil, adhered to the printed piece with an ink or varnish. Since this finishing technique does not require a die, it provides greater flexibility in terms of personalization and can be used on a wide variety of run lengths without issues.

Embossing:

Embossing is the process of creating a die (a personalized metal plate engraved with the image you want to emboss) and utilizing stock (any number of paperboard materials). The die is then pressed onto the stock in a fashion similar to a stamp and the extreme pressure slightly raises the image on the stock. This creates a 3D effect that emphasizes a particular area of the design.

Debossing:

Debossing is almost the opposite of embossing where an image is raised into the die and then imprinted on the print piece, creating an indented effect. While debossing and embossing embellishments are created in a somewhat similar fashion, the visual result is drastically different.

Spot UV:

Spot UV involves a clear, shiny coating which is applied to specific areas of a printed piece, as opposed to coating the entire surface. The outcome is a spectacular contrast between the uncoated matte areas and the shiny UV coated areas which reflect light. Ideal for highlighting specific eye-catching aspects of your printed piece.

Coating and Laminating:

Coating and lamination refer to the processes in which pressure and heat are utilized to adhere a thin layer of plastic (also referred to as laminate) to a paper or card stock. Coating and laminating are primarily used to provide customers with an altered tactile experience; however, these processes also offer a higher vibrancy to printed color gamut and offer additional protection from the elements.

Die Cutting:

While die cutting can be used in various stages of the print manufacturing process it can also be utilized as an embellishment feature. This process utilizes a steel cutting die to cut thin stock materials into a certain shape. Using unique shapes and cuts can peak customers’ attention, give a look at the product inside your packaging, or to create unique art aspects which could not be achieved with other methods.

Sleeking:

Sleeking is an on-demand foil stamping solution primarily applied to short-run digital print. Unlike foil stamping there are no dies needed for sleeking which allows for amazing special effects while remaining budget friendly in some cases. Sleeking technology can apply a simple finish such as gloss or mate, a metallic background such as gold or silver, or even a full coverage to create a unique, brilliant piece.

Superior’s Latest Technologies:

Superior Packaging and Finishing has always strived to be a leader in the print finishing space by incorporating the latest in custom printing technology. In 2021 we have added two new machines to further our commitment in providing our customers with the widest range of services and customization imaginable.

Autobond FL 106 Thermal Laminator:

Superior’s latest acquisition- the Autobond FL 106 Thermal Laminator- is utilized primarily as a 1 or 2 sided sheet-fed, thermal film laminator for long runs. This laminator operates with a maximum sheet size of 106 x 106 cm and a minimum sheet size of 28.5 x 32 cm, with a max speed of 394 ft/min. This machine was custom built specifically for Superior Packaging and Finishing, our version features additional rollers to increase coating stability and durability, made possible by increased roller surface area. Our version also features a rewind roller with pressure sensitive laminate capabilities, ideal for plastics and outdoor signage due to this process being heatless.

This machine also greatly increases the productivity and effectiveness of sleeking jobs because of its ability to print to the edge of a sheet. While not used for every job, sleeking on this machine is good for projects with lots of colors, specialty items, or items with immense detail due to the fact multiple custom colors can be achieved with one pass. This machine also offers increased scuff resistance when compared to foil board and can achieve much cleaner cuts even with heavier paper.

MGI Jetvarnish 3D Evo:

Another recent acquisition by Superior is our MGI Jetvarnish 3D Evo, coined ‘the next generation digital enhancement machine’. With the ability to coat up to 3123 sheets per hour this machine employs the Artificial Intelligence SmartScanner to create an automatic varnish and hot foil registration for inkjet heads over the preprinted sheet. This machine can provide multiple variations of makeready samples in as little as 5 minutes, offering over 2,000 texture options which can be applied anywhere on the sheet. Furthermore; Superior can take any aspect of the preprinted image, select it, and create our own textures with that segment of the preprinted sheet. This machine also possesses the ability to run variable print, keeping lines sharp and ensuring consistency across variable units. Due in part to our close-knit relationship, MGI is developing textures specifically for Superior and its clients which can be expected in the near future.